郭(guo)屯煤(mei)礦以“三(san)減三(san)提”為(wei)目標(biao),信息化為(wei)支(zhi)撐,價值鏈再造為(wei)抓手(shou),堅持抓細抓實成本(ben)管(guan)控、創效增盈等系列工作,努(nu)力(li)建設(she)具有郭(guo)屯特色的“兩化融合”管(guan)理體系。

一、突出價值鏈管理,全面提升發展效率效益

堅(jian)持對(dui)生產全流程進行系(xi)統性(xing)寫實、全方(fang)位優(you)化,梳理剔(ti)除價(jia)值鏈中非增(zeng)值活(huo)動(dong),提升補強增(zeng)值活(huo)動(dong),構建了煤質管控、精益生產、節能降(jiang)耗(hao)、設備管理、精益營銷5條價(jia)值鏈。

1.強化精益煤質管理。突出全(quan)員抓煤(mei)(mei)(mei)(mei)(mei)質(zhi),深化源頭治理(li)、過程管控(kong),建立了控(kong)矸、控(kong)雜(za)、控(kong)水(shui)(shui)(shui)“三控(kong)”管理(li)體系(xi)。1-7月(yue)(yue)份(fen)(fen)精(jing)(jing)煤(mei)(mei)(mei)(mei)(mei)回(hui)(hui)收(shou)(shou)(shou)率(lv)(lv)48.94%,同比提(ti)(ti)高(gao)(gao)7.53%;商品煤(mei)(mei)(mei)(mei)(mei)綜合(he)回(hui)(hui)收(shou)(shou)(shou)率(lv)(lv)77.14%,同比提(ti)(ti)高(gao)(gao)7.57%,原(yuan)煤(mei)(mei)(mei)(mei)(mei)發(fa)熱(re)量4694大(da)卡,較去年7-10月(yue)(yue)份(fen)(fen)提(ti)(ti)高(gao)(gao)489大(da)卡,實(shi)現煤(mei)(mei)(mei)(mei)(mei)質(zhi)創(chuang)效(xiao)9650萬元。特別是(shi)4-6月(yue)(yue)份(fen)(fen)精(jing)(jing)煤(mei)(mei)(mei)(mei)(mei)平(ping)均(jun)產(chan)(chan)率(lv)(lv)56.3%,比去年7-10月(yue)(yue)份(fen)(fen)提(ti)(ti)高(gao)(gao)10.94%;商品煤(mei)(mei)(mei)(mei)(mei)平(ping)均(jun)產(chan)(chan)率(lv)(lv)83.45%,提(ti)(ti)高(gao)(gao)13.88%。一(yi)是(shi)控(kong)矸方面(mian)(mian)(mian)。加強支(zhi)(zhi)架(jia)完好率(lv)(lv)管控(kong),開展(zhan)支(zhi)(zhi)架(jia)工(gong)現場實(shi)操培訓(xun),嚴(yan)(yan)格落實(shi)帶壓(ya)擦頂(ding)移架(jia),嚴(yan)(yan)防架(jia)前(qian)、架(jia)間、端頭漏矸。合(he)理(li)控(kong)制工(gong)作(zuo)面(mian)(mian)(mian)采(cai)高(gao)(gao),過斷層(ceng)嚴(yan)(yan)格分(fen)(fen)(fen)(fen)層(ceng)截割、分(fen)(fen)(fen)(fen)裝(zhuang)分(fen)(fen)(fen)(fen)出;放(fang)頂(ding)煤(mei)(mei)(mei)(mei)(mei)見矸封口(kou),減少(shao)矸石(shi)混入煤(mei)(mei)(mei)(mei)(mei)流(liu);半煤(mei)(mei)(mei)(mei)(mei)巷掘(jue)進(jin)嚴(yan)(yan)控(kong)巷高(gao)(gao)、巷寬(kuan),減少(shao)割矸;巷修施工(gong)或全(quan)巖掘(jue)進(jin)時,利用采(cai)區(qu)雙倉配置,嚴(yan)(yan)格煤(mei)(mei)(mei)(mei)(mei)矸分(fen)(fen)(fen)(fen)離(li)、分(fen)(fen)(fen)(fen)掘(jue)分(fen)(fen)(fen)(fen)出。特殊情(qing)況(kuang)實(shi)行人工(gong)揀矸,原(yuan)煤(mei)(mei)(mei)(mei)(mei)含矸率(lv)(lv)由34.28%最(zui)低(di)(di)降至(zhi)15.82%。二是(shi)控(kong)水(shui)(shui)(shui)方面(mian)(mian)(mian)。各類生產(chan)(chan)設(she)(she)備冷卻水(shui)(shui)(shui)接管外排,工(gong)作(zuo)面(mian)(mian)(mian)有生產(chan)(chan)積(ji)水(shui)(shui)(shui)或老空水(shui)(shui)(shui)集(ji)(ji)(ji)中收(shou)(shou)(shou)集(ji)(ji)(ji)外排,噴(pen)霧、沖塵用水(shui)(shui)(shui)停機停水(shui)(shui)(shui),淋水(shui)(shui)(shui)區(qu)域的皮(pi)帶上方搭設(she)(she)防水(shui)(shui)(shui)雨棚(peng),煤(mei)(mei)(mei)(mei)(mei)倉上口(kou)搭設(she)(she)擋水(shui)(shui)(shui)檐,特別是(shi)膠帶巷積(ji)水(shui)(shui)(shui)區(qu)域每(mei)隔30m施工(gong)臨時排水(shui)(shui)(shui)點,嚴(yan)(yan)控(kong)散(san)水(shui)(shui)(shui)進(jin)入煤(mei)(mei)(mei)(mei)(mei)流(liu),7月(yue)(yue)份(fen)(fen)原(yuan)煤(mei)(mei)(mei)(mei)(mei)全(quan)水(shui)(shui)(shui)降至(zhi)5.03%,有效(xiao)提(ti)(ti)高(gao)(gao)了皮(pi)帶運行安(an)全(quan)系(xi)數和(he)精(jing)(jing)煤(mei)(mei)(mei)(mei)(mei)洗(xi)出率(lv)(lv)。三是(shi)控(kong)雜(za)方面(mian)(mian)(mian),提(ti)(ti)前(qian)標記及(ji)拆(chai)除端頭支(zhi)(zhi)護(hu)材料,防止(zhi)錨桿混入煤(mei)(mei)(mei)(mei)(mei)流(liu);加強除鐵器的維(wei)護(hu)保養和(he)清理(li),保證除鐵器正(zheng)常使用,避免(mian)鐵器二次進(jin)入煤(mei)(mei)(mei)(mei)(mei)流(liu);生產(chan)(chan)現場及(ji)沿線設(she)(she)置雜(za)物回(hui)(hui)收(shou)(shou)(shou)箱,集(ji)(ji)(ji)中回(hui)(hui)收(shou)(shou)(shou)處理(li),并嚴(yan)(yan)格落實(shi)雜(za)物倒追機制。另(ling)外,7月(yue)(yue)20日完成(cheng)煤(mei)(mei)(mei)(mei)(mei)泥(ni)浮(fu)選系(xi)統(tong)改造后(hou),煤(mei)(mei)(mei)(mei)(mei)泥(ni)發(fa)熱(re)量降低(di)(di)至(zhi)2700kcal/kg,降幅(fu)1300kcal/kg,精(jing)(jing)煤(mei)(mei)(mei)(mei)(mei)產(chan)(chan)率(lv)(lv)提(ti)(ti)高(gao)(gao)6.5%,預計年創(chuang)效(xiao)6000萬元。正(zheng)加快施工(gong)一(yi)采(cai)區(qu)矸石(shi)倉,施工(gong)完成(cheng)后(hou)將解決影響礦井煤(mei)(mei)(mei)(mei)(mei)矸分(fen)(fen)(fen)(fen)離(li)的瓶頸,煤(mei)(mei)(mei)(mei)(mei)質(zhi)可由4000大(da)卡提(ti)(ti)升至(zhi)5200大(da)卡,精(jing)(jing)煤(mei)(mei)(mei)(mei)(mei)洗(xi)出率(lv)(lv)由43.3%提(ti)(ti)高(gao)(gao)至(zhi)56.2%,減少(shao)主井提(ti)(ti)矸約5.5萬噸。

2.強化精益生產管理。一是突出科學高效過斷層。按照“一刀一剖面”,每日形成素描圖,通過準確研判斷層揭露情況,構建動態模型,調整支架角度,優化進刀方案。重點強化頂板管控,破碎區域提前注漿治理,實行支架二次注液,加強掛網防護,嚴格帶壓擦頂移架,工作面過斷層周期由28天縮減為19天,減少人工成本投入約39萬元;減少割矸量2.8萬噸。二是突出人工提效。建立“四提一減”分析法(提高放炮、支護、打眼、出矸效率,減少影響時間),對-670m輔助水平軌道巷(xiang)生產流(liu)程進行全面(mian)分析,減少非(fei)增(zeng)值活動(dong),直接工(gong)工(gong)效(xiao)0.090米/工(gong),比定額工(gong)效(xiao)提高13%。三是突出洗選材料管(guan)控。對洗煤廠(chang)濃縮泵房加藥(yao)(yao)量進行寫(xie)實(shi),根據洗選數據優化調整崗位(wei)工(gong)操作(zuo),噸煤泥藥(yao)(yao)耗控制在85g/t以下(xia),較寫(xie)實(shi)前下(xia)降100g/t,節省藥(yao)(yao)劑費(fei)用約(yue)12萬元。

3.強化精益節能管理。重點從設備升級改造、避峰填谷、系統優化、制度管理、電費政策優化等五個方面制定節能降本管控措施,1-7月份同比減少892.91萬度,電費減少603.45萬元,噸煤電耗降低1.36kWh/t。一是堅持設備升級改造。-670m變電所加裝SVG補償裝置,線路損耗降低482KW,年節約電費342萬元。二是嚴格避峰填谷。合理調整生產時間,平均電價同比降低0.005元/度,節約電費42萬元。三是持續優化系統。減少10臺變壓器,減少礦井負荷最大尖峰值,電費同比減少150萬元;開展運輸寫實、皮帶標準化專項治理,皮帶負荷率提高0.64%,每月節約電費、人工費、材料費約4.1萬元;制定實施清污分離排水方案,每天可減少三灰水排放量1800m3,強化污水多(duo)級沉淀,噸水百米電耗比考核(he)指標降低12%。四是加強節電制度(du)管理。制定下發(fa)節電管理制度(du),將用電指標分解至(zhi)班組、頭(tou)面,嚴格落實考核(he)獎(jiang)罰(fa),累(lei)計節約(yue)電量(liang)2.4萬度(du)。五是積極爭(zheng)取電費政策(ce)優惠,嚴格管控功(gong)率因數。

4.強化精益設備管理。一(yi)是(shi)提升(sheng)設備(bei)(bei)(bei)(bei)全生命周(zhou)期(qi)管理。依(yi)托設備(bei)(bei)(bei)(bei)管理共享平(ping)臺(tai)(tai),深(shen)化過程(cheng)管控,對(dui)設備(bei)(bei)(bei)(bei)回(hui)交、領用(yong)、交接及時在設備(bei)(bei)(bei)(bei)平(ping)臺(tai)(tai)發起變(bian)動申請,設備(bei)(bei)(bei)(bei)周(zhou)轉(zhuan)(zhuan)率同比(bi)提高18.8%,集(ji)團內部(bu)調(diao)撥設備(bei)(bei)(bei)(bei)5臺(tai)(tai),盤活資(zi)金(jin)62.84萬元。二是(shi)創新設備(bei)(bei)(bei)(bei)租賃(lin)管理。對(dui)責任單位(wei)管轄范(fan)圍內的設備(bei)(bei)(bei)(bei)收(shou)取租賃(lin)費(fei)(fei)用(yong),增強(qiang)全員設備(bei)(bei)(bei)(bei)管理意(yi)識(shi),逐步消(xiao)除設備(bei)(bei)(bei)(bei)閑置、維護不當造成的浪費(fei)(fei)。截(jie)止7月份(fen)通(tong)過對(dui)試點(dian)單位(wei)清查(cha)對(dui)賬,累計(ji)核實閑置設備(bei)(bei)(bei)(bei)58臺(tai)(tai),市場化結(jie)算租賃(lin)費(fei)(fei)用(yong)1.57萬元。三(san)是(shi)規范(fan)設備(bei)(bei)(bei)(bei)維護管理。在提升(sheng)、壓風、通(tong)風等(deng)主系統安裝(zhuang)振動傳(chuan)感器,采集(ji)點(dian)表數據建立(li)機理模(mo)型,利(li)用(yong)大數據分析手段(duan)定時推送(song)報警信息,將故(gu)障維修保(bao)養向超前維護保(bao)養轉(zhuan)(zhuan)變(bian),減少設備(bei)(bei)(bei)(bei)事故(gu)率,降低非計(ji)劃停產損(sun)失,年(nian)節約(yue)維修費(fei)(fei)用(yong)60余萬元。

5.強化精益營銷管理。一是(shi)建(jian)立訂(ding)單(dan)式客戶維護(hu)看(kan)板(ban)。及時維護(hu)銷(xiao)售(shou)(shou)看(kan)板(ban)及煤炭產(chan)品預警看(kan)板(ban),分析(xi)市場(chang)變化(hua)規律(lv),服務、指導礦井(jing)生產(chan),實現銷(xiao)售(shou)(shou)看(kan)板(ban)管(guan)(guan)理。二是(shi)暢通銷(xiao)售(shou)(shou)渠道。所有副(fu)產(chan)品(洗矸和低質煤)均在自(zi)主(zhu)開發的網絡平(ping)臺競價銷(xiao)售(shou)(shou),1-7月(yue)份實現副(fu)產(chan)品增收(shou)329.16萬元(yuan)。三是(shi)深化(hua)智能(neng)管(guan)(guan)控。健全數字化(hua)驗室,避(bi)免(mian)重復(fu)列表、填(tian)寫質檢(jian)數據,提高工(gong)(gong)作效率;完(wan)善智能(neng)化(hua)煤場(chang)建(jian)設,實現遠程集控、無人管(guan)(guan)理,減(jian)少崗位工(gong)(gong)17人,每(mei)年節約(yue)人工(gong)(gong)費約(yue)16.8萬元(yuan)。

二、突出市場化運行,全面構建縱橫覆蓋的結算模式

以全(quan)面預(yu)算、全(quan)員績效為(wei)(wei)引領,以價(jia)(jia)格為(wei)(wei)紐帶,利(li)用(yong)(yong)(yong)市(shi)(shi)場(chang)(chang)(chang)(chang)(chang)(chang)(chang)價(jia)(jia)值規(gui)律,構(gou)建了“九大(da)要素(su)市(shi)(shi)場(chang)(chang)(chang)(chang)(chang)(chang)(chang)、五級(ji)市(shi)(shi)場(chang)(chang)(chang)(chang)(chang)(chang)(chang)主體、四級(ji)市(shi)(shi)場(chang)(chang)(chang)(chang)(chang)(chang)(chang)交易”的(de)(de)(de)市(shi)(shi)場(chang)(chang)(chang)(chang)(chang)(chang)(chang)化(hua)運(yun)行(xing)(xing)(xing)(xing)管(guan)(guan)(guan)(guan)(guan)(guan)理(li)(li)(li)(li)(li)框架(jia),將(jiang)(jiang)交易劃分為(wei)(wei)量(liang)化(hua)收(shou)購、承責考(kao)核(he)兩大(da)板塊,把內部(bu)工(gong)(gong)序之間的(de)(de)(de)關(guan)系(xi)轉(zhuan)變(bian)為(wei)(wei)等(deng)價(jia)(jia)交換的(de)(de)(de)經濟關(guan)系(xi),實(shi)現(xian)(xian)市(shi)(shi)場(chang)(chang)(chang)(chang)(chang)(chang)(chang)化(hua)的(de)(de)(de)橫向覆蓋和縱向延伸。一(yi)是(shi)產品(pin)市(shi)(shi)場(chang)(chang)(chang)(chang)(chang)(chang)(chang)。采掘、巷修工(gong)(gong)程全(quan)面推行(xing)(xing)(xing)(xing)招投(tou)標(biao)項目化(hua)管(guan)(guan)(guan)(guan)(guan)(guan)理(li)(li)(li)(li)(li),以此提高(gao)勞(lao)動(dong)效率,降低成(cheng)(cheng)本支出。掘進一(yi)工(gong)(gong)區(qu)(qu)(qu)承包2303軌(gui)道順槽掘進項目,工(gong)(gong)效由0.079米/工(gong)(gong)提高(gao)到(dao)0.110米/工(gong)(gong),增(zeng)(zeng)(zeng)幅(fu)39.24%;人(ren)(ren)(ren)均工(gong)(gong)資(zi)(zi)由9719元(yuan)/人(ren)(ren)(ren)增(zeng)(zeng)(zeng)加到(dao)12264.5元(yuan)/人(ren)(ren)(ren),增(zeng)(zeng)(zeng)幅(fu)26.19%。二是(shi)物(wu)資(zi)(zi)供應市(shi)(shi)場(chang)(chang)(chang)(chang)(chang)(chang)(chang)。將(jiang)(jiang)年(nian)度(du)(du)材(cai)料(liao)費(fei)用(yong)(yong)(yong)指標(biao)分解到(dao)采掘、機電(dian)、技術、后勤及(ji)礦(kuang)控(kong)(kong)五個(ge)專(zhuan)業線,由分管(guan)(guan)(guan)(guan)(guan)(guan)礦(kuang)領導自(zi)控(kong)(kong)管(guan)(guan)(guan)(guan)(guan)(guan)理(li)(li)(li)(li)(li);區(qu)(qu)(qu)隊(dui)(科(ke)室)費(fei)用(yong)(yong)(yong)由區(qu)(qu)(qu)隊(dui)制(zhi)定(ding)內部(bu)考(kao)核(he)辦(ban)法,區(qu)(qu)(qu)隊(dui)自(zi)治管(guan)(guan)(guan)(guan)(guan)(guan)理(li)(li)(li)(li)(li);班(ban)(ban)組(zu)將(jiang)(jiang)材(cai)料(liao)費(fei)用(yong)(yong)(yong)落實(shi)到(dao)個(ge)人(ren)(ren)(ren),班(ban)(ban)組(zu)自(zi)主管(guan)(guan)(guan)(guan)(guan)(guan)理(li)(li)(li)(li)(li)。并利(li)用(yong)(yong)(yong)精益物(wu)資(zi)(zi)管(guan)(guan)(guan)(guan)(guan)(guan)理(li)(li)(li)(li)(li)系(xi)統,實(shi)現(xian)(xian)材(cai)料(liao)管(guan)(guan)(guan)(guan)(guan)(guan)理(li)(li)(li)(li)(li)月(yue)(yue)初預(yu)算、實(shi)時管(guan)(guan)(guan)(guan)(guan)(guan)控(kong)(kong)、預(yu)警通(tong)報、重(zhong)點分析、監督整(zheng)改(gai)的(de)(de)(de)閉(bi)環管(guan)(guan)(guan)(guan)(guan)(guan)理(li)(li)(li)(li)(li)。三是(shi)租(zu)賃(lin)(lin)市(shi)(shi)場(chang)(chang)(chang)(chang)(chang)(chang)(chang)。對機電(dian)設備及(ji)周轉(zhuan)物(wu)資(zi)(zi)實(shi)行(xing)(xing)(xing)(xing)租(zu)賃(lin)(lin)管(guan)(guan)(guan)(guan)(guan)(guan)理(li)(li)(li)(li)(li),提高(gao)利(li)用(yong)(yong)(yong)率,減(jian)少資(zi)(zi)金(jin)(jin)占(zhan)用(yong)(yong)(yong)。1-7月(yue)(yue)份周轉(zhuan)物(wu)資(zi)(zi)通(tong)過租(zu)賃(lin)(lin)節約投(tou)入190.81萬(wan)元(yuan)。四是(shi)電(dian)力市(shi)(shi)場(chang)(chang)(chang)(chang)(chang)(chang)(chang)。運(yun)用(yong)(yong)(yong)能(neng)耗(hao)監測系(xi)統,每天(tian)統計礦(kuang)井電(dian)費(fei)發生情況,實(shi)現(xian)(xian)動(dong)態管(guan)(guan)(guan)(guan)(guan)(guan)控(kong)(kong)。對電(dian)費(fei)管(guan)(guan)(guan)(guan)(guan)(guan)理(li)(li)(li)(li)(li)實(shi)行(xing)(xing)(xing)(xing)日清(qing)月(yue)(yue)結,指導各(ge)用(yong)(yong)(yong)電(dian)單(dan)位(wei)合理(li)(li)(li)(li)(li)選型、維(wei)(wei)護(hu)使用(yong)(yong)(yong)設備,提高(gao)設備運(yun)行(xing)(xing)(xing)(xing)效率。五是(shi)人(ren)(ren)(ren)力資(zi)(zi)源市(shi)(shi)場(chang)(chang)(chang)(chang)(chang)(chang)(chang)。根據(ju)礦(kuang)井生產接續,制(zhi)定(ding)月(yue)(yue)度(du)(du)、季度(du)(du)、年(nian)度(du)(du)定(ding)編定(ding)員方案(an),認真(zhen)開(kai)展人(ren)(ren)(ren)力資(zi)(zi)源專(zhuan)項整(zheng)頓,開(kai)展區(qu)(qu)(qu)隊(dui)員工(gong)(gong)素(su)能(neng)測評,優化(hua)人(ren)(ren)(ren)力資(zi)(zi)源結構(gou)。六是(shi)服務市(shi)(shi)場(chang)(chang)(chang)(chang)(chang)(chang)(chang)。打造“一(yi)站(zhan)式”運(yun)輸(shu)服務市(shi)(shi)場(chang)(chang)(chang)(chang)(chang)(chang)(chang),通(tong)過物(wu)料(liao)運(yun)輸(shu)數量(liang)、形式及(ji)距離寫實(shi),形成(cheng)(cheng)交易單(dan)價(jia)(jia),實(shi)行(xing)(xing)(xing)(xing)虛擬(ni)貨幣結算,提高(gao)輔助運(yun)輸(shu)設備滿載率,運(yun)輸(shu)效率提高(gao)10%。七是(shi)維(wei)(wei)修市(shi)(shi)場(chang)(chang)(chang)(chang)(chang)(chang)(chang)。機修廠(chang)在實(shi)現(xian)(xian)“班(ban)(ban)清(qing)班(ban)(ban)結”的(de)(de)(de)基礎上,實(shi)行(xing)(xing)(xing)(xing)獨(du)立(li)(li)核(he)算、自(zi)負盈虧,進一(yi)步挖(wa)掘維(wei)(wei)修市(shi)(shi)場(chang)(chang)(chang)(chang)(chang)(chang)(chang)潛力,設備完好(hao)率提升6.8%。八是(shi)洗(xi)銷市(shi)(shi)場(chang)(chang)(chang)(chang)(chang)(chang)(chang)。對洗(xi)選管(guan)(guan)(guan)(guan)(guan)(guan)理(li)(li)(li)(li)(li)及(ji)營銷管(guan)(guan)(guan)(guan)(guan)(guan)理(li)(li)(li)(li)(li)進行(xing)(xing)(xing)(xing)市(shi)(shi)場(chang)(chang)(chang)(chang)(chang)(chang)(chang)化(hua)收(shou)購,對煤管(guan)(guan)(guan)(guan)(guan)(guan)科(ke)運(yun)銷單(dan)價(jia)(jia)按1.61元(yuan)/噸(dun)(dun)收(shou)購,對洗(xi)煤廠(chang)原煤入洗(xi)單(dan)價(jia)(jia)按0.73元(yuan)/噸(dun)(dun)、精煤洗(xi)選單(dan)價(jia)(jia)1.81元(yuan)/噸(dun)(dun)收(shou)購,激發自(zi)主管(guan)(guan)(guan)(guan)(guan)(guan)理(li)(li)(li)(li)(li)、自(zi)主提升效能(neng)。九是(shi)資(zi)(zi)金(jin)(jin)市(shi)(shi)場(chang)(chang)(chang)(chang)(chang)(chang)(chang)。為(wei)(wei)確保市(shi)(shi)場(chang)(chang)(chang)(chang)(chang)(chang)(chang)化(hua)工(gong)(gong)作的(de)(de)(de)深入開(kai)展,在實(shi)現(xian)(xian)公平交易的(de)(de)(de)前提下,建立(li)(li)資(zi)(zi)金(jin)(jin)市(shi)(shi)場(chang)(chang)(chang)(chang)(chang)(chang)(chang),完善“以豐補歉”調(diao)節機制(zhi),區(qu)(qu)(qu)隊(dui)儲(chu)備賬戶實(shi)行(xing)(xing)(xing)(xing)月(yue)(yue)度(du)(du)核(he)算、季度(du)(du)清(qing)算、半年(nian)兌現(xian)(xian)、年(nian)底(di)清(qing)零模式,規(gui)范市(shi)(shi)場(chang)(chang)(chang)(chang)(chang)(chang)(chang)化(hua)運(yun)作。

三、突出“兩化融合”,全面建設精益精細管控體系

以(yi)市場化(hua)管(guan)(guan)理為(wei)基礎,以(yi)精益(yi)思想植(zhi)入和(he)精益(yi)管(guan)(guan)理工具應用為(wei)手段,持續完善(shan)管(guan)(guan)理流程(cheng)和(he)經營機(ji)制,實現市場化(hua)、精益(yi)化(hua)管(guan)(guan)理相(xiang)互支撐(cheng)、有機(ji)融合。

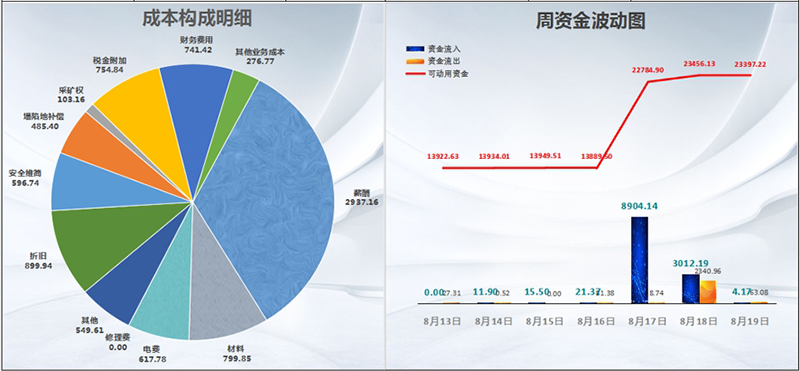

1.堅持對市場主體進行精益提升。一是礦井層級。根據管(guan)理會(hui)(hui)計(ji)的“量(liang)(liang)本利”分(fen)析(xi)、全(quan)面預算(suan)管(guan)理,每天形成(cheng)以產量(liang)(liang)、收入、成(cheng)本支出、利潤(run)完成(cheng)、現金流(liu)量(liang)(liang)等為(wei)主要內容的經(jing)(jing)營管(guan)理簡報。圍繞利潤(run)目標,用會(hui)(hui)計(ji)語言說明(ming)經(jing)(jing)濟(ji)運行狀態,建立數(shu)學(xue)模型(xing),

為生(sheng)產決策提(ti)供依據。二(er)是(shi)專業層(ceng)級(ji)。通過市(shi)場結(jie)算(suan)鏈條,將(jiang)安全生(sheng)產、工(gong)(gong)(gong)程質量(liang)、文明(ming)生(sheng)產、“一通三防”、防沖管(guan)(guan)理(li)等精益生(sheng)產項目,進行貨幣(bi)化(hua)管(guan)(guan)理(li),納入(ru)市(shi)場化(hua)結(jie)算(suan),實現市(shi)場化(hua)、精益化(hua)融合。三是(shi)區(qu)隊(dui)(dui)(dui)層(ceng)級(ji)。將(jiang)成(cheng)本(ben)控制中心下沉(chen)至(zhi)區(qu)隊(dui)(dui)(dui),根據人工(gong)(gong)(gong)費(fei)(fei)、材(cai)料(liao)費(fei)(fei)、電費(fei)(fei)、維修費(fei)(fei)等構(gou)成(cheng)的標準成(cheng)本(ben),建立提(ti)效(xiao)、節支、增收的盈收自主管(guan)(guan)控平(ping)臺(tai),實行班(ban)清(qing)日結(jie)。每天形成(cheng)“區(qu)隊(dui)(dui)(dui)盈收表(biao)”,提(ti)高(gao)工(gong)(gong)(gong)資(zi)分配透(tou)明(ming)度,實現自主經營(ying)、自負(fu)盈虧,減(jian)少成(cheng)本(ben)管(guan)(guan)控責任盲區(qu)。四(si)是(shi)班(ban)組(zu)層(ceng)級(ji)。以集(ji)團公司(si)勞動定額為基礎,制定“千分制”,實現勞動量(liang)化(hua)管(guan)(guan)理(li),統一區(qu)隊(dui)(dui)(dui)內(nei)部工(gong)(gong)(gong)資(zi)計分標準,提(ti)高(gao)班(ban)組(zu)自主管(guan)(guan)理(li)水平(ping)。五是(shi)員工(gong)(gong)(gong)層(ceng)級(ji)。計劃通過OEC科(ke)學計分,規范(fan)管(guan)(guan)理(li),實現日事日畢(bi)、日清(qing)日高(gao),打破區(qu)隊(dui)(dui)(dui)、班(ban)組(zu)層(ceng)級(ji)的“大(da)鍋飯(fan)”,營(ying)造提(ti)工(gong)(gong)(gong)效(xiao)、減(jian)支出(chu)、學技能的濃厚氛(fen)圍。

2.持續強化信息化支撐。一(yi)是(shi)上線精益(yi)薪(xin)酬(chou)管(guan)理系統。在采掘區隊成功運行,改(gai)變(bian)了(le)(le)過(guo)去使用(yong)電子表格管(guan)理數據效率(lv)低、易丟(diu)(diu)失、難統計的(de)現狀,提高(gao)了(le)(le)薪(xin)酬(chou)核(he)算工(gong)作的(de)透明度(du)和效率(lv),將精細(xi)(xi)化管(guan)理的(de)目標向班組、現場延伸,提高(gao)精細(xi)(xi)化管(guan)理程(cheng)度(du),系統結算準確率(lv)達到90%以上,并且實現職(zhi)工(gong)收入一(yi)鍵查詢(xun)。二是(shi)上線精益(yi)物(wu)(wu)(wu)資(zi)管(guan)理系統。為材料消耗細(xi)(xi)化到班組、個(ge)人提供了(le)(le)信(xin)息(xi)化支撐,實現了(le)(le)礦井對物(wu)(wu)(wu)資(zi)管(guan)理的(de)全生命周期(qi)業務流程(cheng)信(xin)息(xi)化,減少(shao)了(le)(le)物(wu)(wu)(wu)資(zi)丟(diu)(diu)失及浪費(fei)現象,加(jia)快了(le)(le)周轉(zhuan)物(wu)(wu)(wu)資(zi)流轉(zhuan)。僅通過(guo)系統的(de)自動利(li)庫功能,1-7月盤活積壓物(wu)(wu)(wu)資(zi)268項,金額60.14萬元。

3.推行反對浪費自主改善。全(quan)面分析識別過(guo)量(liang)生產、運輸浪(lang)費、庫存(cun)浪(lang)費、等待浪(lang)費、過(guo)度加工、不良(liang)品、動(dong)作浪(lang)費、管理浪(lang)費“八大(da)浪(lang)費”共計56項,各單位逐條制定(ding)整(zheng)改措施,解決顯(xian)性(xing)和(he)隱(yin)性(xing)浪(lang)費點(dian),優化(hua)價值流程。通(tong)過(guo)反(fan)對浪(lang)費活動(dong),節約成本約56萬(wan)元(yuan),獎勵優秀項目5200元(yuan)。

4.推行“7S”目視管理。“物(wu)資(zi)超(chao)市”劃區管(guan)理,清理長期積壓無利用價(jia)值物(wu)資(zi)27項,制作(zuo)目視化看板,提高(gao)收發(fa)物(wu)資(zi)效率,減(jian)少(shao)倉庫(ku)保(bao)管(guan)員(yuan)(yuan)2人(ren),每年(nian)節約人(ren)工成(cheng)本(ben)約23萬(wan)元。開展(zhan)機(ji)修(xiu)廠工位定置管(guan)理,減(jian)少(shao)了人(ren)、機(ji)、料的浪費,實現了安全有保(bao)障、工效有提高(gao)、員(yuan)(yuan)工職業素養(yang)有提升(sheng)。