一、礦井概況

山東省邱集煤(mei)(mei)礦(kuang)有限公司位于德州市齊河縣馬集鎮境內(nei),是黃河北煤(mei)(mei)田第一對試驗型(xing)礦(kuang)井(jing)(jing)(jing)(jing)。2003年12月31日(ri)正(zheng)式投產,核定生(sheng)產能(neng)力達到(dao)75萬噸/年。礦(kuang)井(jing)(jing)(jing)(jing)采用(yong)立井(jing)(jing)(jing)(jing)開(kai)拓,中央并列式通風,可采煤(mei)(mei)層(ceng)(ceng)為7、10、11、13煤(mei)(mei)層(ceng)(ceng)。經多年開(kai)采7煤(mei)(mei)臨近(jin)枯(ku)竭,開(kai)采下(xia)組(zu)煤(mei)(mei)成為礦(kuang)井(jing)(jing)(jing)(jing)的(de)必(bi)由(you)之(zhi)路。下(xia)組(zu)煤(mei)(mei)(11、13煤(mei)(mei)層(ceng)(ceng))總(zong)儲量近(jin)2億t,占礦(kuang)井(jing)(jing)(jing)(jing)資源量的(de)87%。下(xia)組(zu)煤(mei)(mei)深受頂底板灰巖水害的(de)威脅,水文地(di)質(zhi)條件為復(fu)雜型(xing)。

二、礦井水文地質條(tiao)件(jian)

井田內的含(han)水(shui)(shui)(shui)(shui)(shui)(shui)層(ceng)(ceng)自上而下(xia)主要(yao)是太(tai)原(yuan)組一灰(hui)、二煤灰(hui)、三灰(hui)、四五(wu)灰(hui)、徐灰(hui)和奧陶系灰(hui)巖。其中(zhong)一灰(hui)、二灰(hui)、三灰(hui)已基本疏干,四五(wu)灰(hui)為(wei)11煤直(zhi)接充水(shui)(shui)(shui)(shui)(shui)(shui)含(han)水(shui)(shui)(shui)(shui)(shui)(shui)層(ceng)(ceng),平(ping)均(jun)(jun)厚(hou)度9.8m,單(dan)位涌水(shui)(shui)(shui)(shui)(shui)(shui)量(liang)0.19-1.38L/s·m,富(fu)(fu)水(shui)(shui)(shui)(shui)(shui)(shui)性(xing)中(zhong)等-強(qiang);徐灰(hui)含(han)水(shui)(shui)(shui)(shui)(shui)(shui)層(ceng)(ceng),單(dan)位涌水(shui)(shui)(shui)(shui)(shui)(shui)量(liang)0.11-1.21L/s·m,平(ping)均(jun)(jun)厚(hou)度10m,富(fu)(fu)水(shui)(shui)(shui)(shui)(shui)(shui)性(xing)中(zhong)等-強(qiang);奧灰(hui)區域(yu)厚(hou)度700m左右,單(dan)位涌水(shui)(shui)(shui)(shui)(shui)(shui)量(liang)0.02-4.04L/s·m,富(fu)(fu)水(shui)(shui)(shui)(shui)(shui)(shui)性(xing)弱至強(qiang),是四五(wu)灰(hui)、徐灰(hui)的直(zhi)接充水(shui)(shui)(shui)(shui)(shui)(shui)含(han)水(shui)(shui)(shui)(shui)(shui)(shui)層(ceng)(ceng)。經多次放水(shui)(shui)(shui)(shui)(shui)(shui)試(shi)驗查明四五(wu)灰(hui)、徐灰(hui)與徐奧灰(hui)之(zhi)間存(cun)在(zai)垂向水(shui)(shui)(shui)(shui)(shui)(shui)力聯系。

三、下組煤開采技術

1.地面(mian)區域治理(li)技術

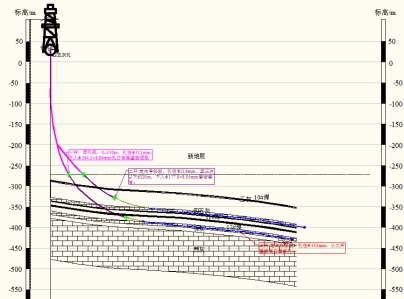

經(jing)過充分的技(ji)術論證和考察,2016年確定(ding)通(tong)過采(cai)用(yong)地面順(shun)層水平定(ding)向(xiang)(xiang)鉆探+高壓(ya)注漿技(ji)術進(jin)行超前(qian)區(qu)域(yu)治(zhi)理。超前(qian)區(qu)域(yu)治(zhi)理將水害由被(bei)動防(fang)治(zhi)向(xiang)(xiang)主(zhu)動治(zhi)理進(jin)行了轉變,其優(you)勢主(zhu)要表現(xian)在區(qu)域(yu)、手段(duan)、時(shi)效3個方面。

地面順層水平鉆(zhan)孔結(jie)構(gou)由(you)直井、造斜和(he)水平段組成。鉆(zhan)孔由(you)一個主孔和(he)若(ruo)干分支孔組成,根據需要確(que)定不(bu)同的(de)(de)布置方式(shi),并根據注(zhu)漿(jiang)(jiang)擴散距離確(que)定合理孔間(jian)距,治理中實(shi)行逢漏、分段注(zhu)漿(jiang)(jiang)相結(jie)合,注(zhu)漿(jiang)(jiang)終壓(ya)(ya)為(wei)目的(de)(de)巖溶含水層靜水壓(ya)(ya)力(li)的(de)(de)1.5-2.0倍。

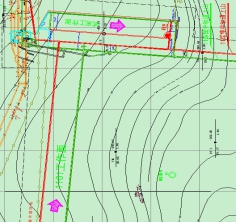

在(zai)分析水(shui)文(wen)地質條(tiao)件、總結前期(qi)的治(zhi)理(li)(li)經驗的基礎上,不斷(duan)優(you)化(hua)方(fang)案設計,針對11煤(mei)頂板(ban)為四五灰巖(yan)層,含水(shui)層難(nan)以(yi)疏干(gan)的現(xian)狀(zhuang),提出并實(shi)施了(le)(le)(le)“頂底板(ban)同注(zhu)”技(ji)術(shu)(shu)方(fang)案(專(zhuan)利號(hao)201710170051.2);同時不斷(duan)改進(jin)施工工藝,針對前期(qi)扇(shan)狀(zhuang)布置水(shui)平鉆孔,存(cun)在(zai)鉆孔間距不均一(0-70米)、順層段短、漿(jiang)液擴(kuo)(kuo)散不均問題(ti),聯(lian)合石(shi)油單位進(jin)行(xing)科技(ji)攻(gong)關,研發了(le)(le)(le)“在(zai)淺(qian)埋深條(tiao)件下(xia)等距離分支鉆孔”技(ji)術(shu)(shu)(專(zhuan)利號(hao)2018109792466);結合完善的水(shui)文(wen)動態(tai)監測系統,根據(ju)注(zhu)漿(jiang)擴(kuo)(kuo)散范圍、注(zhu)漿(jiang)壓力(li)、水(shui)位的變化(hua),調(diao)整(zheng)注(zhu)漿(jiang)參(can)數,進(jin)行(xing)了(le)(le)(le)黃河北(bei)煤(mei)田定(ding)向鉆進(jin)精準注(zhu)漿(jiang)水(shui)害治(zhi)理(li)(li)技(ji)術(shu)(shu)研究,形成了(le)(le)(le)一套具有自主知識產權(quan)的水(shui)害治(zhi)理(li)(li)的技(ji)術(shu)(shu),實(shi)現(xian)了(le)(le)(le)我(wo)國頂底板(ban)雙重灰巖(yan)威脅煤(mei)層開采(cai)的突破。

2.采區設計優化

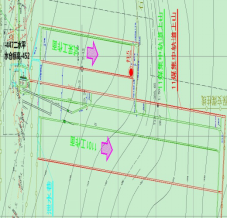

一采(cai)區初步設計為(wei)(wei)走向開采(cai)方案,結合肥城礦區經驗,根(gen)據礦井水害防(fang)治要求,為(wei)(wei)保(bao)證可能出水后人員的撤離(li),優化(hua)為(wei)(wei)傾(qing)向開采(cai)方案,其優點(dian)為(wei)(wei):

(1)排水(shui)系統完(wan)善,預防水(shui)災的能力強(qiang),安全性(xing)高。通過泄(xie)水(shui)巷,水(shui)直接進入水(shui)倉,防止(zhi)了工作面積水(shui)。

(2)安(an)全出口多,有利于防災避災。采區(qu)上山與安(an)全通道貫通后,采區(qu)形成三個安(an)全出口,不(bu)僅避災路線短(duan),而且人員避災時還可(ke)以避免經過采區(qu)最低(di)點(dian)。

(3)采(cai)區內的(de)(de)掘(jue)進、回(hui)采(cai)均為仰采(cai)的(de)(de)作業方式(shi),可以減輕(qing)作業時突水對施工人員的(de)(de)威脅(xie)。后期回(hui)采(cai)時,還可以防止因巷(xiang)道起伏(fu)造成積(ji)水影響巷(xiang)道的(de)(de)供風。

(4)通風方式(shi):通過應用110工(gong)法,1101工(gong)作(zuo)(zuo)面(mian)實現(xian)了Y型通風。軌道順(shun)槽(cao)和(he)膠帶順(shun)槽(cao)兩(liang)巷進風,沿(yan)空(kong)留巷段(duan)回風,保證了工(gong)作(zuo)(zuo)面(mian)兩(liang)順(shun)槽(cao)均(jun)為新鮮風流(liu),大大改善了工(gong)作(zuo)(zuo)面(mian)工(gong)作(zuo)(zuo)環境。

經(jing)多次對比、優(you)化(hua),采用(yong)了傾向開采方案(an),同時施工安全通道(dao),并設置專門的泄水巷。

采(cai)區(qu)設計走向與(yu)傾向開(kai)采(cai)對比圖

3.井下探(tan)查補注(zhu)技術(shu)

在區(qu)域治(zhi)理(li)(li)過程中,采用了(le)多技術手(shou)段對治(zhi)理(li)(li)情況進行(xing)的探測,并(bing)驗證治(zhi)理(li)(li)效果。多次在地(di)面(mian)采用電(dian)法進行(xing)大區(qu)域探測。按照(zhao)《煤礦防治(zhi)水細則(ze)》要求,在井下采用物探、鉆探方(fang)法進行(xing)效果驗證,堅持逢掘必(bi)探,對工作面(mian)采用2種物探方(fang)法進行(xing)相互驗證。

在井下多地(di)點、多角(jiao)度、多方向、分(fen)序(xu)次施(shi)工(gong)頂(ding)板(ban)四(si)五灰(hui)、底(di)(di)板(ban)徐奧灰(hui)鉆(zhan)(zhan)(zhan)孔(kong)(kong)(kong)(kong),實現(xian)對區域(yu)內注漿效果的立體探(tan)查(cha)。鉆(zhan)(zhan)(zhan)孔(kong)(kong)(kong)(kong)即為探(tan)查(cha)孔(kong)(kong)(kong)(kong),也(ye)是補(bu)注孔(kong)(kong)(kong)(kong),實現(xian)一(yi)孔(kong)(kong)(kong)(kong)多用(yong)(yong)。施(shi)工(gong)頂(ding)板(ban)四(si)五灰(hui)切頂(ding)鉆(zhan)(zhan)(zhan)孔(kong)(kong)(kong)(kong)1000多個,治理后(hou)頂(ding)板(ban)已經疏(shu)干;對于底(di)(di)板(ban)探(tan)查(cha)鉆(zhan)(zhan)(zhan)孔(kong)(kong)(kong)(kong)單(dan)孔(kong)(kong)(kong)(kong)涌(yong)水(shui)量小于3.0m/h,將作為水(shui)文觀測孔(kong)(kong)(kong)(kong);涌(yong)水(shui)量大于3.0m/h的鉆(zhan)(zhan)(zhan)孔(kong)(kong)(kong)(kong)采用(yong)(yong)黃土水(shui)泥補(bu)注加固,然后(hou)根據第(di)一(yi)序(xu)次鉆(zhan)(zhan)(zhan)孔(kong)(kong)(kong)(kong)水(shui)量和注漿量施(shi)工(gong)第(di)二序(xu)次鉆(zhan)(zhan)(zhan)孔(kong)(kong)(kong)(kong)和檢(jian)查(cha)孔(kong)(kong)(kong)(kong)。

4.頂板預裂卸壓開采技術

針(zhen)對11煤的(de)(de)直接頂(ding)板(ban)為(wei)四五灰巖層,不易冒落的(de)(de)特點,采用頂(ding)板(ban)預(yu)(yu)裂卸壓開采,全垮(kua)落式管理頂(ding)板(ban)。地面(mian)注漿改(gai)造后,頂(ding)板(ban)四五灰的(de)(de)物理和力學性質發生(sheng)了改(gai)變,為(wei)控制頂(ding)板(ban)垮(kua)落,通(tong)過經驗借鑒、數(shu)值(zhi)模(mo)擬(ni)等手(shou)段(duan),提出并實踐“頂(ding)板(ban)灰巖全閉合預(yu)(yu)裂卸壓開采技術”。

該技術對復合堅硬(ying)頂(ding)(ding)板(ban)進行(xing)預裂切縫爆破(po)(po),切斷了(le)采空(kong)區與周邊巷(xiang)(xiang)道(dao)區域頂(ding)(ding)板(ban)之間的(de)直接(jie)聯(lian)系,采空(kong)區頂(ding)(ding)板(ban)全(quan)部垮落(luo),將(jiang)頂(ding)(ding)板(ban)壓力(li)傳(chuan)遞到(dao)采空(kong)區底板(ban),減(jian)少對煤層底板(ban)的(de)破(po)(po)壞深(shen)度。切頂(ding)(ding)卸壓是目的(de),留(liu)巷(xiang)(xiang)作(zuo)(zuo)為(wei)副產品(首采面(mian)(mian)兩巷(xiang)(xiang)全(quan)留(liu)巷(xiang)(xiang)),留(liu)設巷(xiang)(xiang)道(dao)可為(wei)下(xia)一個工作(zuo)(zuo)面(mian)(mian)服務,運用并改進了(le)110工法。

5.智能化開采技術

利(li)用工(gong)(gong)(gong)作(zuo)面(mian)(mian)穩(wen)定(ding)性(xing)頂板(ban)條件(jian),大力實(shi)施以“提高裝(zhuang)備水平、優(you)化(hua)(hua)(hua)生(sheng)產系統(tong)(tong)、優(you)化(hua)(hua)(hua)勞動(dong)(dong)(dong)(dong)組(zu)織(zhi)”為主要內容(rong)的(de)(de)(de)“一提雙優(you)”工(gong)(gong)(gong)作(zuo)實(shi)踐,著力構(gou)建“工(gong)(gong)(gong)藝現(xian)代(dai)化(hua)(hua)(hua)、生(sheng)產自(zi)(zi)動(dong)(dong)(dong)(dong)化(hua)(hua)(hua)、運行(xing)集(ji)控(kong)(kong)化(hua)(hua)(hua)、管理信息(xi)化(hua)(hua)(hua)、隊伍專業(ye)化(hua)(hua)(hua)”新(xin)型生(sheng)產模式,開(kai)(kai)啟“智能(neng)化(hua)(hua)(hua)開(kai)(kai)采(cai)”新(xin)時代(dai)。工(gong)(gong)(gong)作(zuo)面(mian)(mian)集(ji)成了液(ye)壓(ya)支架電控(kong)(kong)系統(tong)(tong)、采(cai)煤(mei)機自(zi)(zi)動(dong)(dong)(dong)(dong)化(hua)(hua)(hua)系統(tong)(tong)、語(yu)音(yin)通信系統(tong)(tong)、工(gong)(gong)(gong)作(zuo)面(mian)(mian)視頻(pin)輔助(zhu)系統(tong)(tong)與順(shun)槽集(ji)控(kong)(kong)自(zi)(zi)動(dong)(dong)(dong)(dong)化(hua)(hua)(hua)系統(tong)(tong),在地(di)面(mian)(mian)與井下實(shi)現(xian)一鍵自(zi)(zi)動(dong)(dong)(dong)(dong)化(hua)(hua)(hua)順(shun)序啟停、液(ye)壓(ya)支架的(de)(de)(de)遠程(cheng)與自(zi)(zi)動(dong)(dong)(dong)(dong)化(hua)(hua)(hua)控(kong)(kong)制、采(cai)煤(mei)機的(de)(de)(de)遠程(cheng)與自(zi)(zi)動(dong)(dong)(dong)(dong)化(hua)(hua)(hua)控(kong)(kong)制、視頻(pin)輔助(zhu)干(gan)預與自(zi)(zi)動(dong)(dong)(dong)(dong)跟隨等核心功能(neng)。工(gong)(gong)(gong)作(zuo)面(mian)(mian)建立(li)了設備云平臺監控(kong)(kong),利(li)用礦井的(de)(de)(de)萬兆網(wang)絡和(he)自(zi)(zi)動(dong)(dong)(dong)(dong)化(hua)(hua)(hua)集(ji)控(kong)(kong)系統(tong)(tong),將記憶割煤(mei)、人工(gong)(gong)(gong)輔助(zhu)、調度監控(kong)(kong)一體化(hua)(hua)(hua),實(shi)現(xian)工(gong)(gong)(gong)作(zuo)面(mian)(mian)的(de)(de)(de)智能(neng)化(hua)(hua)(hua)開(kai)(kai)采(cai)。

1101智能(neng)化(hua)工作面“四新技術”的(de)成(cheng)功應用,將職(zhi)工從危險的(de)工作面解(jie)放到安(an)(an)全的(de)順槽監控中心,有效降(jiang)低了職(zhi)工的(de)勞(lao)動強度,實現了“4D”歸零目標(biao),提(ti)升了礦井安(an)(an)全保障(zhang)能(neng)力。

6.安全措施的保障

1)強排系統。針(zhen)對開采(cai)下組煤(mei),礦井在(zai)原(yuan)有(you)排水系統的(de)基礎上,建(jian)立了強排系統;在(zai)泵房安設兩臺(tai)直排電泵,排水能(neng)力1000m/h。

2)疏(shu)水(shui)降壓。在工(gong)作面開(kai)采(cai)中(zhong),為減少開(kai)采(cai)對底(di)板破壞的(de)深度和強度,采(cai)取了疏(shu)水(shui)降壓的(de)技術手段,以(yi)開(kai)采(cai)線為中(zhong)心,前、中(zhong)、后相結合,控制放(fang)水(shui)的(de)范圍(wei),并(bing)建立了疏(shu)水(shui)降壓臺賬、繪制工(gong)作面涌水(shui)量觀(guan)測圖表。

3)強(qiang)化預(yu)警。不斷完善礦井(jing)水(shui)(shui)(shui)文動(dong)態(tai)監測預(yu)警系(xi)統和突水(shui)(shui)(shui)預(yu)警系(xi)統,對井(jing)田范圍內主要充水(shui)(shui)(shui)含水(shui)(shui)(shui)層和工(gong)作(zuo)面區域的水(shui)(shui)(shui)位、水(shui)(shui)(shui)溫、水(shui)(shui)(shui)壓等(deng)進行動(dong)態(tai)觀測,并建立(li)礦井(jing)水(shui)(shui)(shui)質數據庫。為礦井(jing)水(shui)(shui)(shui)害治理(li)提供(gong)更有效的監測、分析。

4)預裂爆破管理頂板

針對邱集煤(mei)礦11煤(mei)堅硬頂(ding)(ding)(ding)板(ban)(ban)難垮(kua)落或大面積(ji)垮(kua)落難控制(zhi)、應力(li)(li)傳遞(di)可能造成的(de)(de)底(di)板(ban)(ban)破(po)(po)壞、突水(shui)等隱(yin)患問題,提出了(le)超前(qian)深孔(kong)聚(ju)能預(yu)裂爆(bao)破(po)(po)技術,通過(guo)強制(zhi)放頂(ding)(ding)(ding)預(yu)切(qie)(qie)斷回(hui)采(cai)區(qu)(qu)域頂(ding)(ding)(ding)板(ban)(ban)與周圍頂(ding)(ding)(ding)板(ban)(ban)的(de)(de)直接聯(lian)系(xi),使(shi)得工作面推(tui)過(guo)后采(cai)空區(qu)(qu)頂(ding)(ding)(ding)板(ban)(ban)沿切(qie)(qie)縫線垮(kua)落,減少了(le)采(cai)空區(qu)(qu)懸頂(ding)(ding)(ding)面積(ji),改變了(le)巷道(dao)頂(ding)(ding)(ding)板(ban)(ban)受力(li)(li)情況(kuang),實現(xian)了(le)切(qie)(qie)頂(ding)(ding)(ding)留巷;頂(ding)(ding)(ding)板(ban)(ban)垮(kua)落后,采(cai)空區(qu)(qu)頂(ding)(ding)(ding)板(ban)(ban)上附礦壓(ya)通過(guo)冒落的(de)(de)頂(ding)(ding)(ding)板(ban)(ban)傳遞(di)到底(di)板(ban)(ban)上,改變了(le)采(cai)空區(qu)(qu)底(di)板(ban)(ban)的(de)(de)應力(li)(li)環境,降低(di)應力(li)(li)對底(di)板(ban)(ban)破(po)(po)壞。

四、主要經驗

1.在進(jin)行黃河北煤田受(shou)頂(ding)底(di)板(ban)雙重水害(hai)威(wei)脅煤層水害(hai)治理(li)過程中,通過采用地(di)面區域(yu)順層鉆孔+高壓(ya)注漿技術(shu)(shu)進(jin)行水害(hai)超前治理(li),實現(xian)了水害(hai)治理(li)技術(shu)(shu)新(xin)突破(po)。“頂(ding)底(di)板(ban)同(tong)注”技術(shu)(shu),解(jie)決(jue)了11煤受(shou)雙重灰巖威(wei)脅的問題。

采(cai)用(yong)淺埋深地面順(shun)層等(deng)距(ju)離(li)分(fen)支鉆(zhan)孔(kong)鉆(zhan)探技(ji)術施(shi)工(gong)(gong),在同條件(jian)同工(gong)(gong)程(cheng)量下,較鉆(zhan)孔(kong)采(cai)用(yong)扇(shan)形布置治(zhi)理面積增加15%;單孔(kong)可節省治(zhi)理費(fei)用(yong)100多萬元(yuan);在后期施(shi)工(gong)(gong)中全部采(cai)用(yong)該項技(ji)術,可節省治(zhi)理費(fei)用(yong)近2000萬元(yuan)。

采(cai)用(yong)黃河(he)北煤田(tian)灰巖含水層裂隙精(jing)準注漿技術,每平米(mi)可節約(yue)水泥用(yong)量(liang)約(yue)5%,可節省治理費用(yong)約(yue)4000萬元。自動化(hua)造漿控制(zhi)系統,解(jie)決了(le)漿液攪拌不(bu)均的(de)問(wen)題,實現了(le)精(jing)確的(de)控制(zhi)漿液的(de)比重(zhong),降低了(le)揚塵概(gai)率,提高了(le)效能。

2.立(li)體(ti)化水害防控理(li)念

經過(guo)對(dui)(dui)下組(zu)煤的(de)(de)(de)(de)治(zhi)(zhi)理經驗的(de)(de)(de)(de)總(zong)(zong)結(jie)(jie),形成了(le)立(li)體(ti)式水(shui)(shui)(shui)害防控(kong)理念(nian),總(zong)(zong)結(jie)(jie)了(le)一(yi)套(tao)完(wan)整的(de)(de)(de)(de)治(zhi)(zhi)理技術(shu)。立(li)體(ti)式水(shui)(shui)(shui)害防治(zhi)(zhi)理念(nian),包(bao)括時(shi)(shi)域(yu)和空域(yu)兩個方面(mian),時(shi)(shi)域(yu)包(bao)括:礦(kuang)井(jing)建(jian)井(jing)階段查(cha)清井(jing)田(tian)的(de)(de)(de)(de)水(shui)(shui)(shui)文地(di)質(zhi)條(tiao)件勘查(cha)、礦(kuang)井(jing)單獨水(shui)(shui)(shui)文地(di)質(zhi)單元勘察(cha)、超前(qian)區(qu)域(yu)治(zhi)(zhi)理的(de)(de)(de)(de)探查(cha)、井(jing)下的(de)(de)(de)(de)鉆探探查(cha)、采(cai)(cai)掘工程的(de)(de)(de)(de)水(shui)(shui)(shui)文監(jian)測、水(shui)(shui)(shui)資(zi)源的(de)(de)(de)(de)利用規(gui)劃等(deng)。空域(yu)包(bao)括:大區(qu)域(yu)地(di)面(mian)治(zhi)(zhi)理與(yu)(yu)工作面(mian)疏(shu)水(shui)(shui)(shui)降壓結(jie)(jie)合,井(jing)田(tian)地(di)層與(yu)(yu)治(zhi)(zhi)理地(di)層的(de)(de)(de)(de)結(jie)(jie)合,原巖應力(li)場、采(cai)(cai)動應力(li)場、水(shui)(shui)(shui)力(li)場的(de)(de)(de)(de)結(jie)(jie)合;大構造、小斷層、裂隙展布的(de)(de)(de)(de)結(jie)(jie)合。不斷推(tui)進單一(yi)水(shui)(shui)(shui)害治(zhi)(zhi)理的(de)(de)(de)(de)轉變,對(dui)(dui)勘、探、治(zhi)(zhi)、評、防、監(jian)、控(kong)整體(ti)規(gui)劃,實(shi)現“防、治(zhi)(zhi)、控(kong)”一(yi)體(ti)化(hua)(hua)、立(li)體(ti)化(hua)(hua)。

五、治理效果

邱(qiu)集礦(kuang)11煤(mei)(mei)頂、底(di)板(ban)薄層(ceng)(ceng)灰巖含水(shui)層(ceng)(ceng)治理工(gong)程(cheng)開展3年來,效果顯著,主要(yao)表現:一是實現黃河北煤(mei)(mei)田11煤(mei)(mei)的(de)首次(ci)揭(jie)露,實現了頂底(di)板(ban)雙重威脅煤(mei)(mei)層(ceng)(ceng)開采(cai)(cai)的(de)新突破,初期解放11煤(mei)(mei)儲量(liang)約400萬噸。二(er)是11煤(mei)(mei)安(an)全(quan)掘(jue)進(jin)巷道12000米,形成了排(pai)水(shui)、通風(feng)、供電、運輸系統。三是總(zong)結出11煤(mei)(mei)沿頂板(ban)四五灰掘(jue)進(jin)過(guo)程(cheng)中(zhong)正常(chang)涌(yong)水(shui)量(liang)小于3m/h,底(di)板(ban)徐(xu)灰檢查(cha)孔(kong)小于10m/h基本(ben)能夠保證安(an)全(quan)開采(cai)(cai)。四是試采(cai)(cai)面完成安(an)全(quan)試采(cai)(cai),首采(cai)(cai)工(gong)作面已推采(cai)(cai)160m。五是治理過(guo)程(cheng)中(zhong)形成了一套(tao)完整的(de)適應邱(qiu)集煤(mei)(mei)礦(kuang)水(shui)文地質(zhi)條件(jian)的(de)水(shui)平(ping)定向鉆孔(kong)頂底(di)板(ban)同注漿新技(ji)術(shu)、頂板(ban)全(quan)閉合預裂卸壓(ya)開采(cai)(cai)技(ji)術(shu)、記憶式(shi)智(zhi)能化工(gong)作面建設。

在下組煤(mei)開(kai)(kai)采(cai)(cai)過(guo)程中(zhong),根據礦(kuang)井水(shui)文地質(zhi)條件(jian),采(cai)(cai)用新治理技術,并不斷進行科技創新,形成了以“立(li)體化(hua)水(shui)害防(fang)治”、“預(yu)裂(lie)式(shi)卸(xie)壓開(kai)(kai)采(cai)(cai)”、“智能化(hua)開(kai)(kai)采(cai)(cai)”為核心的(de)、具有自主(zhu)產權的(de)下組煤(mei)開(kai)(kai)采(cai)(cai)關鍵(jian)技術,為解放黃河北煤(mei)田區域內(nei)大量優質(zhi)煤(mei)炭資源奠定了堅(jian)實(shi)的(de)基礎(chu),積累了較為豐富的(de)防(fang)治水(shui)、開(kai)(kai)采(cai)(cai)技術和實(shi)踐經(jing)驗。